On Demand

Fractography in Plastics Failures

On Demand is accessible ONLY if you registered for the event or purchased on demand access. NOTE: Access will require your member or non-member customer login. Forgot your password? Click here.

For assistance, contact customerrelations@4spe.org.

Click button below to access on demand.

Summary

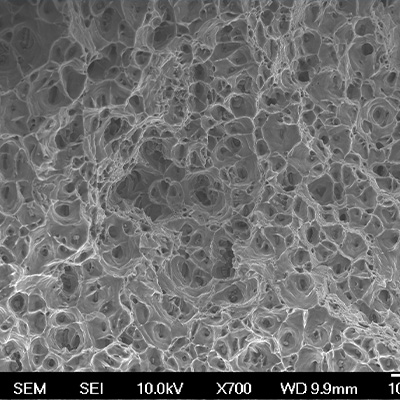

The goal of a failure analysis is to discern the mechanism and cause of the component failure - essentially to identify how and why the part broke. Fractography plays critical role in this, particularly in identifying the failure mode. Cracking occurs as a result of the exertion of stresses, both external and internal, on a component. Cracking is simply a stress relief mechanism in which the material is attempting to reach a lower energy state. Plastics fail through a disentanglement mechanism in which polymer chains slide past each other.

The features on the fracture surface are created based upon a number of parameters:

- Type of material and formulation constituents;

- Type of applied forces (tensile, compression, shear);

- Magnitude of forces;

- Frequency of forces (continuous, intermittent, rapidly applied);

- Environmental effects (temperature, presence of chemical).

Much of the information regarding the failure mechanism can be gleaned by interpreting the features found on the fracture surface. The examination and interpretation of the fracture surface is known as fractography. This presentation explores some common plastics failure mechanisms and the associated telltale features.

About the Speaker

Jeffrey A. Jansen is the Engineering Manager and a Partner at The Madison Group, an independent plastics engineering and consulting firm. Jeff is a proven plastic professional with more than 30 years of experience solving problems and addressing opportunities related to polymeric materials. He specializes in failure analysis, material identification and selection, as well as compatibility, aging, and lifetime prediction studies for thermoplastic materials. Jeff has performed over 5,000 investigations, both for industrial clients and as a part of litigation. He is a regular presenter on the SPE webinar series, covering a wide range of topics related to plastics failure, material performance, testing, and polymer technology. Jeff is a graduate of Carroll College and the Milwaukee School of Engineering.

This educational program is provided as a service of SPE. The views and opinions expressed on this or any SPE educational program are those of the Speaker(s) and/or the persons appearing with the Speaker(s) and do not necessarily reflect the views and opinions of the Society of Plastics Engineers, Inc. (SPE) or its officials, employees or designees. To comment or to present an opposing or supporting opinion, please contact us at info@4SPE.org.

Refund Policy for SPE Webinars

No refunds are available for SPE Webinars.

Copyright & Permission to Use

SPE may take photographs and audio/video recordings during the event, pre-event meetings and receptions that may include attendees within sessions, networking areas, exhibition areas, and other areas associated with the event both inside and outside of the venue. By registering for this event, all attendees are providing permission for SPE to use this material at its discretion on SPE's websites, marketing materials, and publications. SPE retains ownership of copyright to all photographs and audio/video recording obtained at this event and attendees may request copies of any material in which they are included.

Anti-Trust Statement

- No discussion among members, volunteers, or staff, which attempts to arrive at any agreement regarding prices, terms or conditions of sale, distribution, volume, territories, or customers;

- No activity or communication which might be construed as an attempt to prevent any person or business entity from gaining access to any market or customer for goods or services or any business entity from obtaining services or a supply of goods;

- No activity or communication which might be construed as an agreement to refrain from purchasing or using any materials, equipment, services or supplies of or from any supplier; or

- No other activity which violates anti-trust or applicable laws aimed at preventing unfair competition.