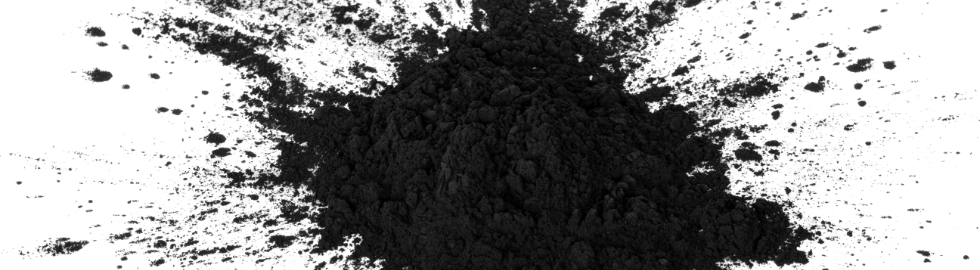

The optimization of carbon black (CB) content and process conditions in rubber formulations is critical for ensuring performance consistency, especially in lab-scale rubber processing aimed at quality control and research and development. By mimicking full-scale production processes in the laboratory, formulators can improve scalability and reduce the risk of performance deviation during scale-up. Furthermore, modifications in carbon black structure—such as surface area, porosity, and aggregate morphology—directly influence its reinforcing behavior, making careful process design essential.

This study addresses key challenges inherent in rubber formulation development. A major difficulty lies in reconciling process differences between various internal mixers. Even mixers of similar design can exhibit variability due to wear over time, which affects fill factor and energy input. As a result, achieving a 1:1 process translation between lab and production mixers is seldom feasible. Additionally, distinguishing between qualitative assessments (e.g., visual dispersion) and quantitative measurements (e.g., tensile strength, dynamic mechanical analysis) introduces variability that complicates optimization efforts. Temperature control presents another core challenge, as frictional heat generated during mixing can exceed the cooling system’s capacity, potentially altering material properties and mixing behavior.

To address these issues, a combination of rheometry, dispersion analysis, and mechanical property testing was employed. These instruments enabled precise evaluation of compound consistency, dispersion quality, and reinforcement effects under varying CB contents and mixing parameters. Through iterative testing, optimal process conditions were identified that balance carbon black loading, mixer energy input, and thermal management.

In conclusion, fine-tuning the interaction between carbon black characteristics and processing conditions can significantly enhance formulation reliability and performance. By systematically controlling variables and using a robust measurement framework, lab-scale processes can better emulate production conditions, ultimately facilitating more predictable scale-up and material behavior.