SPE Workshop

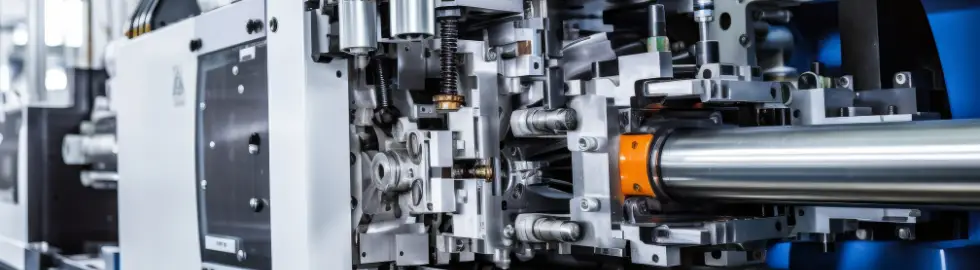

Injection Mold Setup and the Process of Tool and Product Trialing

April 11, 14 and 16, 2025

11:00 AM to 1:00 PM EDT

Online

Summary

Mastering the injection molding process goes beyond simply setting up a machine—it's about ensuring efficiency, precision, and consistency from trial to final production. This comprehensive workshop takes participants through the essential phases of mold setup, tool and product trialing, and quality control, offering a deep dive into best practices for achieving optimal cycle times and part quality.

Designed for professionals with die-setting experience, this session will cover:

- Preparing for a new tool trial, including material specifications and quality standards

- Understanding tool design, cavity layout, and runner systems

- Best practices for heating, cooling, and ejection mechanisms

- Key insights into troubleshooting and fine-tuning for production efficiency

Join us to enhance your technical expertise, gain hands-on knowledge, and refine your approach to achieving seamless mold setups and high-quality production runs!

Agenda

(Click each session to expand)

Outline

Part and Tool Design

- Part Geometry & Size: Shape, size, and implications on tooling

- Wall Thickness & Flow Path: Variations, impact on filling, and venting

- Cavity & Runner System: Balancing, cavity filling, and sequential gating

- Tooling Considerations: Cooling channels, water flow, temperature control

- Ejection & Venting: Stroke, ejection methods, and tool maintenance

Material

- Amorphous vs. Semi-Crystalline Polymers: Flow behavior and key differences

- Material-Specific Considerations: PP, PE, PA, ABS, PMMA, PC

- Processing Parameters: Drying, machine settings, and auxiliary equipment

- Material Handling: Virgin vs. reprocessed materials, mixing, and common issues

Resources

Go to Session 1

Outline

Machine Considerations

- Machine Movement & Settings: Impact on material and part quality

- Cycle Times & Quality Control: Optimization for efficiency

- Production Cell Layout: Auxiliary equipment integration

Die Setting Process

- Tool Preparation & Changeover: Cleaning, placement, and alignment

- Machine & Work Cell Setup: Programming, auxiliary equipment, and robotics

- Quality Assurance: Master samples, documentation, and tracking

Machine Processing Parameters

- Shot Size & Screw Functions: Stages of material processing

- Injection Parameters: Speed, pressure, time, and material flow behavior

- Cooling System: Temperature control and polymer impact

Resources

Go to Session 2

Outline

Identifying & Understanding Faults

- Recognizing Defects: Patterns, cycle-to-cycle variations, and common faults

- Process Stability Checks: Machine cycle consistency, environmental factors

- Root Cause Analysis: Material drying, temperature fluctuations, operator feedback

Troubleshooting & Rectification

- Tracking Changes: Process adjustments and maintaining records

- Systemic Approach: Considering total production environment, not just machine settings

- Long-Term Implications: Adjustments and their cascading effects on material flow

Resources

Go to Session 3

Registration Information

| SPE Premium Member |

$540 |

| SPE Members |

$600 |

| Nonmembers |

$800 |

Register Now

Not an SPE member? Join today and attend this workshop at a discounted rate!

Instructor

Wilhelm Morgan

CEO

WOMCORP Pty Ltd

With a career spanning several decades, Wilhelm Morgan began his professional journey in the foundry industry as a jobbing mould and core maker. His four-year apprenticeship quickly led to a leadership role, training other apprentices by his second year. After eight years in heavy engineering, he transitioned into the plastics industry, where he developed expertise in injection molding, extrusion, rotational molding, and other processing techniques.

Leveraging his deep understanding of metal flow, he gained unique insights into polymer flow, part design, and tool development. His contributions to manufacturing innovation earned him multiple awards for enhancing production efficiency, optimizing tooling and process parameters, and improving quality control.

Throughout his career, he advanced through leadership roles, from leading hand to production manager in injection molding. His passion for education led him to government colleges, where he became the first instructor to simultaneously teach plastics processing, part and tool design, CAD, leadership, and management across three institutions.

For over 20 years, he has operated his own training school, educating engineers, technicians, and production managers across various companies. His expertise has been recognized through numerous published papers and speaking engagements at international conferences. Today, he continues to support the plastics manufacturing industry through training and consultancy.

Questions? Contact:

For questions, contact Iván D. López.

Who Should Attend?

Polymer process engineers, Quality process engineers, Production managers, Polymer technicians, Tooling Engineers, Tool and product designers, Die setters, Trouble shooting technicians, Material sellers and Students.

Why Should You Attend?

Are you working in injection molding and looking to refine your expertise in mold setup and product trialing?

Whether you're a process technician, toolmaker, or production engineer, mastering the setup and trial process is crucial for ensuring efficiency, precision, and consistent part quality!

Do you want to understand the key steps in preparing for a new tool trial, from material specifications to quality standards?

Are you a toolmaker or die-setter looking to optimize heating, cooling, and ejection mechanisms for better performance?

As a production engineer, do you need to fine-tune cycle times, troubleshoot common issues, and enhance overall process efficiency?

Are you aiming to gain hands-on knowledge in cavity layout, runner systems, and best practices for achieving seamless mold setups?

If the answer is YES to any of these questions, this workshop is for you! Join Wilhelm Morgan for an engaging and in-depth session on mastering injection mold setup, tool and product trialing, and quality control. Don't miss this opportunity to enhance your skills and achieve top-tier production results!