Workshop

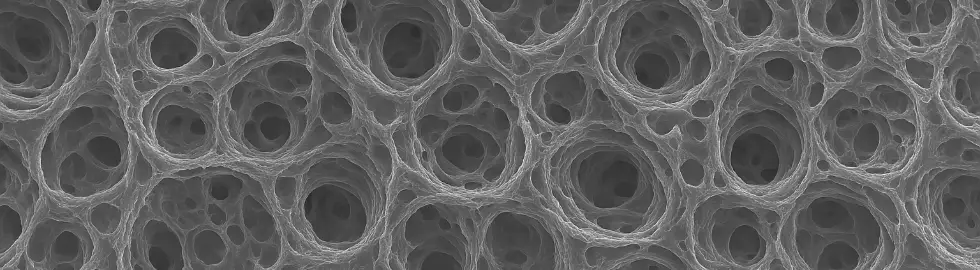

Polymer Fractography — Case studies

November 3, 5 & 7, 2025

All workshop days are from 11:00 AM to 12:30 PM EST.

Online

Summary

Understanding why polymers fail and what their fracture surfaces reveal is essential for anyone working with materials, quality control, or failure analysis. This training offers a deep dive into polymer fractography, focusing on real-world case studies rather than just theory. Through hands-on analysis and expert-led discussions, participants will learn to interpret fracture surfaces, identify failure mechanisms such as brittle and ductile fractures, fatigue, and stress cracking, and assess the impact of environmental and processing factors. This course provides practical tools to enhance failure investigations and prevent future material issues.

Registration Information

| SPE Premium Member |

$405 |

| SPE Members |

$450 |

| Nonmembers |

$600 |

Register Now

Not an SPE member? Join today and attend this workshop at a discounted rate!

Instructor

Anne-Laure Esquirol

Forensic Engineer Head of the Materials Group

CEP Forensic

LinkedIn

"Anne-Laure Esquirol is a forensic engineer head of the Materials Group at CEP Forensic, in Montréal, Canada, and is specializing in the investigation of material failures, particularly in polymer and plastic components. With 12 years’ experience in site investigations, laboratory testing, and microscopic material characterization, she provides expert analysis on failure mechanisms, degradation, and underperformance of polymer and other materials.

Her expertise spans polymer processing techniques, fracture analysis, material resistance, and more. Holding a Master's in Chemical Engineering Research from Polytechnique Montréal and a Bachelor's in Materials Engineering from l’Institut des sciences de l’ingénieur de Toulon et du Var (ISITV), France, she has contributed to multiple research projects and industry seminars. As a member of the Society of Plastics Engineers and a frequent analyzer on polymer failures, she brings both technical depth and practical insights to material diagnostics and failure prevention."

Questions? Contact:

For questions, contact Iván D. López.

Who Should Attend?

The targeted audience for the "Polymer Fractography – Case Studies" workshop includes:

- Materials Engineers and Scientists: Professionals involved in the development, testing, and optimization of polymer materials.

- Quality Control and Assurance Specialists: Those responsible for assessing and ensuring product quality in manufacturing environments.

- Failure Analysis Experts: Engineers and analysts focused on identifying root causes of material failures.

- Polymer and Plastics Engineers: Professionals working with polymers in various industries, such as automotive, packaging, and electronics.

- Research and Development Professionals: Individuals working on innovations and improvements in polymer materials.

- Production and Process Engineers: Those overseeing manufacturing processes and aiming to minimize defects and failures.

- Consultants and Technical Advisors: Experts providing guidance on material selection, failure prevention, and troubleshooting.

The workshop’s focus on practical, real-world case studies makes it particularly valuable for professionals who need to interpret fracture surfaces, understand failure mechanisms, and apply this knowledge to solve problems in industrial settings.

Why Should You Attend?

Are you struggling to understand why polymer components fail during use or testing?

This workshop provides in-depth training on interpreting fracture surfaces and identifying failure mechanisms, helping you pinpoint root causes accurately.

Do you want to reduce customer complaints and protect your company’s reputation?

Gain practical tools to prevent failures, enhance product reliability, and deliver consistent quality, leading to higher customer satisfaction.

Are you involved in litigation due to plastic part failures and need to understand the root causes?

Learn how to analyze fractures, identify failure mechanisms, and use fractography to build a solid technical understanding for legal cases.

Are you dealing with complex material failures and need a structured approach for analysis?

Learn proven techniques to analyze brittle and ductile fractures, fatigue, stress cracking, and more, enabling effective failure investigations.